Safety for drives with FSI 800

SIL2/PLd certified heavy duty incremental encoders

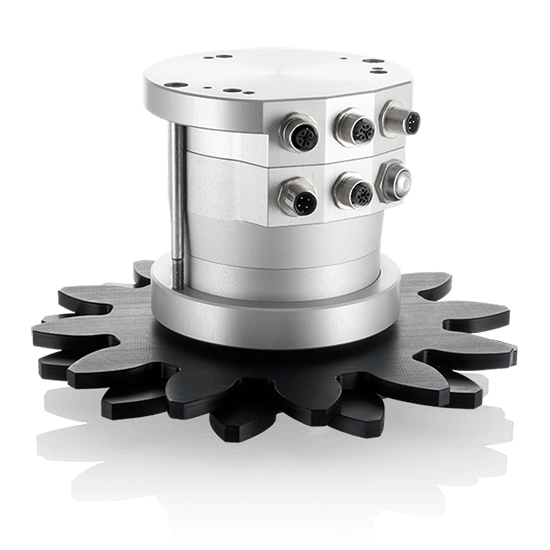

Achieve functional safety SIL2 and PLd category 3 in accordance with EN ISO 13849-1 with the FSI 800 series from Leine Linde. These functionally safe heavy duty incremental encoders are made with a slip-free shaft or hollow-shaft construction.

Simplify machine design

The square wave signals are monitored internally in the FSI 800 series encoders. If faults are detected, the encoder signals will enter safe state. Thanks to the integrated safety solution, a second encoder or sensor for redundancy will no longer be needed for a functionally safe installation. This will save space and reduce the need for cables, which even further decreases the system’s vulnerability to environmental factors, disturbances, wear and tear.

The FSI 800 series fulfills the mechanical fault exclusion requirement due to the slip-free solution for the shaft installation. The FSI 862 hollow shaft encoder contains a guiding pin which requires a matching adapter shaft to be mounted. The FSI 850 shaft encoder has a key nut on to the shaft ensuring safe mounting in couplings with keyway.

Handling cables over 300 metres

Up until now, the only single encoder solution available on the market has been using a 1Vpp signal, which is not appropriate in these harsh environments, due to its weak signal of 5 Vdc. Therefore, the solution is the FSI 800 series with HCHTL signals for 9-30 Vdc, which also meets the demand for long cables (over 300 metres). This is perfectly designed for critical applications such as those in the steel and the paper industry, where production runs for 24 hours per day, seven days a week, protected in accordance with the requirements for SIL2/PLd, category 3, machinery directive in related C-standard.