Customized encoders tailored to your needs

We understand that every operation is unique, and standard solutions may not always meet your specific requirements. That's why we offer tailored encoders and solutions precisely to your needs.

Made for you

Can't find the encoder you need in our standard product range? Just contact us and our expert team will work closely with you to design and produce a custom encoder that perfectly suits your application.

Read our customer stories and explore the wide range of encoder solutions we successfully delivered to meet our customer’s specific needs. If you are interested in a similar product or solution or want to discuss other customization possibilities, just let us know. We’re here for you.

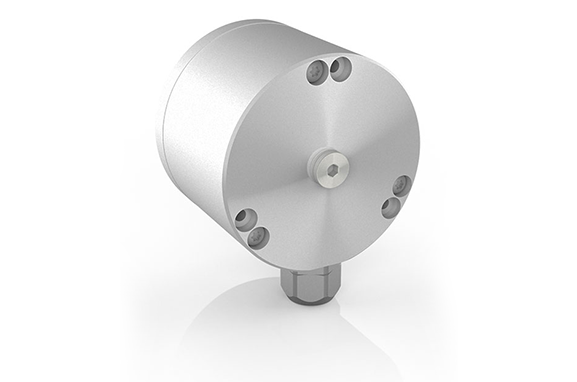

Challenging nut processing environment

One of Leine Linde’s Danish customers is a manufacturer of machinery for the food industry. In one particular case they were building a machine for drying and roasting nuts, to be shipped to an end customer in the US. A lot of dust is created as nuts are processed, creating a challenging environment for encoders.

To adapt a RHI 593 encoder to the dusty environment, our engineers added an inlet for pressurized air to the housing. By applying a pressure of about 0.2 to 0.5 bar inside the encoder, any dust particles are kept out of the enclosure.

Low temperature heavy duty 865 duo encoder

Leine Linde's encoders have a broad operating temperature span, already in their standard design. The encoders in the 800 series are available in variants for temperatures down to -40ºC and up to +100ºC.

For one of our users, this was not enough, as the solution they were building had to work flawlessly in temperatures down to -50ºC.

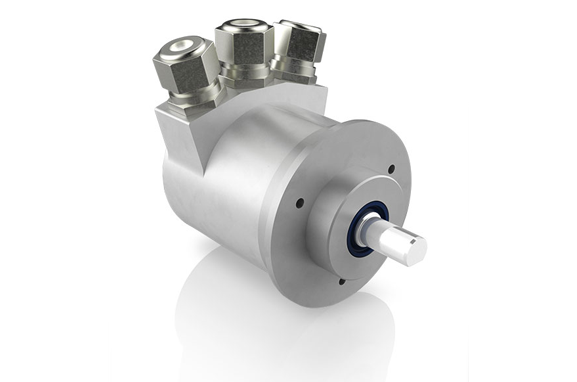

Air pressurized splash-proof stainless steel encoder

Some of the liquids that are processed in the food industry are really acidic. Cleaning agents and other aggressive substances are frequently used in and around the machines and encoders used must withstand occasional splashes and exposure to such fluids.

For one of these machine manufacturers, Leine Linde developed a splash-proof and corrosion resistant absolute encoder used for positioning and synchronization in a packaging and filling machine used in the dairy industry.

Encoder with GORE-TEX valve for extra humid environments

The ISA 698 encoder with GORE-TEX valve was originally developed for rock drilling rigs in the mining industry. The new GORE-TEX valve prevents moisture from accumulating inside the encoder. Instead, it enables a one-way release of moisture to keep the inside of the encoder dry, for optimal operation.

Industrial encoder with retrofit flange

One of Leine Linde’s customers in the Korean steel industry recently wanted to replace an existing encoder from another encoder manufacturer with a modern Leine Linde inductive 600 series encoder equipped with a PROFIBUS interface. The existing mount was an old-fashioned ø65 mm flange.

To simplify installation, Leine Linde engineers created a retrofit flange for the desired encoder model.

Get in touch!

At Leine Linde, we take great pride in giving you personal support. Please contact us for assistance and technical support. All questions are welcome! We work worldwide.